Your rebuild takes 45 seconds. Rotating an assembly stutters at 5 FPS. Opening a drawing locks the software for 10 minutes. The timeline burns while SolidWorks crawls.

This guide shows how to make SolidWorks run faster on Windows 11 and Windows 10. You will learn hardware optimization, critical system settings, assembly strategies, and diagnostic methods that eliminate lag without expensive hardware upgrades or risky workarounds.

Why Is SolidWorks Running Slow?

SolidWorks performance depends on three layers: hardware architecture, software configuration, and modeling methodology. A bottleneck at any layer kills speed. Fix all three to transform sluggish rebuilds into instant responses.

Diagnose Your SolidWorks Performance Bottleneck

Quick Fixes to Make SolidWorks Run Faster

Fast Performance Optimization

Start here for immediate speed improvements without hardware changes

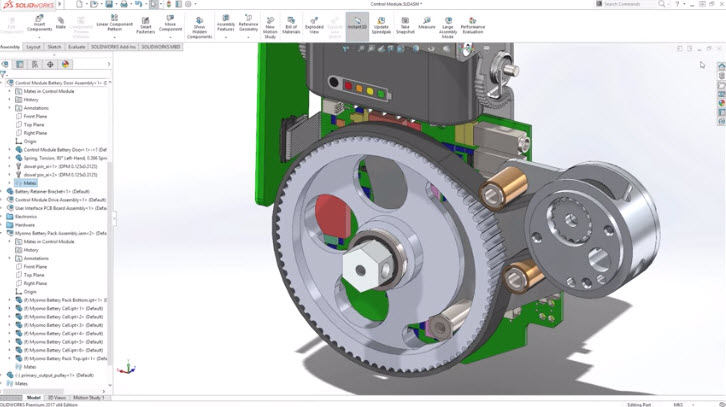

Understanding SolidWorks CPU Architecture

SolidWorks is built on the Parasolid kernel which uses parametric history-based modeling. Your feature tree is a chronological sequence where Feature B depends on Feature A, Feature C depends on Feature B, and so on. When you edit Feature A, the kernel must recalculate A, then B, then C in strict sequential order to maintain valid topology. This dependency chain makes parallelization mathematically impossible for core rebuild operations.

The primary driver of rebuild performance is single-threaded CPU speed. A processor running at 5.5 GHz with 8 cores will rebuild models far faster than a 64-core server chip running at 2.5 GHz. More cores help with rendering, simulation solvers, and background tasks, but the modeling experience depends entirely on high clock frequency and Instructions Per Clock efficiency.

CPU Performance Impact on Rebuild Times

Real world comparison of different processor architectures

Low single-core speed

High single-core speed

5400 RPM mechanical drive

28x faster load time

Critical System Options for Performance

SolidWorks tessellates mathematical surfaces into triangle meshes for display. The Image Quality slider controls mesh density. High settings exponentially increase triangle count. A simple washer at High quality can carry 20,000 triangles versus 40 triangles at Low. If inserted 5,000 times in an assembly, that difference becomes 100 million triangles that crush GPU performance.

Hardware Requirements and Optimization

SolidWorks Hardware Requirements by Use Case

| Component | Minimum (Parts Only) | Recommended (Assemblies) | Optimal (Large Assemblies) |

|---|---|---|---|

| CPU | 4-core @ 3.5 GHz | 8-core @ 4.5+ GHz | 16-core @ 5.0+ GHz (i9/Ryzen 9) |

| RAM | 16 GB | 32 GB | 64 GB or 128 GB |

| GPU | Entry Quadro/RTX | RTX A2000-A4000 | RTX A5000/A6000 |

| Storage (OS/SW) | NVMe SSD Required | 500 GB NVMe Gen 3 | 1 TB NVMe Gen 4 |

| Page File | 32 GB fixed | 64 GB fixed (2x RAM) | 128 GB fixed (2x RAM) |

GPU Configuration and Driver Settings

SolidWorks only enables advanced shading features like RealView on certified graphics cards. NVIDIA RTX (formerly Quadro) and AMD Radeon Pro series are tested and supported. Consumer gaming cards are technically capable but software-locked. Using gaming drivers or Windows Update drivers causes graphical glitches, disappearing faces, and crashes during rotation.

Virtual Memory and RAM Configuration

Windows default automatic page file management dynamically resizes the file during sessions which causes temporary I/O freezes. SolidWorks and Windows commit virtual memory addresses regardless of physical RAM usage. If the commit limit is reached, the application crashes with Low Resources warning even if physical RAM shows empty space.

Best practice for CAD stability: Set a custom fixed size page file at 2x your physical RAM. For a 32 GB workstation, set both Initial Size and Maximum Size to 65,536 MB (64 GB). This ensures a massive commit limit and prevents page file fragmentation. Access this in Control Panel > System > Advanced system settings > Performance Settings > Advanced tab > Virtual Memory.

Large Assembly Mode Strategies

Drawing Performance and Detailing Mode

For many users, 3D models are fast but 2D drawings are excruciatingly slow. Generating drawing views involves projecting complex 3D geometry onto 2D planes, a mathematically intensive process. A drawing of a 5,000-part assembly that normally takes 10 minutes to load and update will open in Detailing Mode in 30 seconds.

Detailing Mode allows opening massive drawings without loading underlying 3D model data. You can add dimensions, annotations, balloons, revision clouds, move views, print to PDF, and save changes. The limitation is you cannot create new drawing views that require projecting 3D geometry because the geometry is not loaded. This is the standard workflow for checking, annotating, and printing large drawing packages.

Drawing Optimization Workflow

Reduce drawing load times from 10 minutes to 30 seconds

Imported Geometry and Assembly Management

Vendor parts imported as STEP, IGES, or Parasolid files are often dirty, containing sliver faces, gaps, or excessive detail. A single bad face (mathematical error in surface definition) can force SolidWorks to switch entirely to software rendering for that face, bypassing the GPU and causing severe lag.

Always run Import Diagnostics (Tools > Evaluate > Import Diagnostics) after breaking the 3D Interconnect link. Attempt to Heal All errors. If a part cannot be healed and is not critical for design, consider remodeling it as a simple placeholder block. Use the Defeature tool to remove internal details like gears, windings, and screws that are irrelevant to top-level assembly. Use Delete Face with Delete and Patch to remove embossed text, logos, or knurling which add thousands of unnecessary triangles.

Network Storage and File Access

SolidWorks assembly files are databases of pointers referencing part files. Opening a single assembly may trigger read requests for thousands of referenced parts. If these files reside on a network server, the latency of SMB protocol means handshake time for thousands of files accumulates into massive delays even if total data transfer is small.

Never work continuously on files directly over network shares. Manual method: copy project folder to local SSD, edit, and copy back. PDM method: use SolidWorks PDM which automatically manages the cache process, copying files to local drive on demand and checking them back when done. This ensures you always work at SSD speeds while maintaining central server backup.

Diagnostics with SolidWorks Rx

When performance degrades, guessing is inefficient. SolidWorks Rx provides data-driven diagnostics. Found in Windows Start Menu under SolidWorks Tools, Rx allows launching in two special modes for testing.

Conclusion

SolidWorks performance optimization requires alignment across hardware, software configuration, and modeling methodology. Start with hardware foundation: install NVMe SSDs, ensure 32 GB plus RAM, and set page file to 2x RAM fixed size. Install certified GPU drivers specific to your SolidWorks version.

Move to software configuration by turning off Verification on Rebuild, enabling Enhanced Graphics Performance, and fixing template Image Quality settings to Low. Finally, adopt efficient methodology by using Detailing Mode for drawings, Lightweight or LDR for assemblies, and immediately fixing imported geometry with diagnostics.

By systematically executing this three-layer approach, engineering teams eliminate friction from the design process and achieve the speed SolidWorks is capable of delivering.

FAQ

Why is SolidWorks so slow on my computer

Most slowness comes from three bottlenecks: CPU single-core speed too low for rebuild operations, incorrect GPU drivers causing graphics lag, or insufficient RAM forcing Windows to page to disk. Additionally, having Verification on Rebuild enabled and High image quality in templates multiplies calculation times unnecessarily.

What is the best CPU for SolidWorks performance

SolidWorks rebuild operations are single-threaded, so prioritize high clock frequency over core count. Optimal choices are Intel Core i7/i9 13th-14th Gen or AMD Ryzen 7/9 7000-9000 series with 8 to 16 cores sustaining turbo boost above 4.5 GHz. A 5.5 GHz 8-core chip outperforms a 2.5 GHz 64-core server CPU for modeling.

How do I make SolidWorks assemblies load faster

Enable Automatically load components lightweight in System Options > Assemblies. This loads only header info and graphics data, skipping feature history. For massive assemblies, use Large Design Review mode which opens in seconds instead of minutes. Work from local SSD storage, never directly from network drives.

Should I turn off Verification on Rebuild

Yes, turn it off immediately. Verification on Rebuild checks every face against every other face on every rebuild, multiplying calculation time by 2x to 10x on complex parts. Only enable temporarily when diagnosing specific geometry errors. Standard error checking is sufficient for daily modeling work.

What graphics card do I need for SolidWorks

Use certified workstation GPUs: NVIDIA RTX A2000 through A6000 or AMD Radeon Pro series. More important than the card itself is installing the certified driver version tested for your specific SolidWorks year from the hardware certification page. Gaming drivers or Windows Update drivers cause crashes and graphical glitches.

How much RAM does SolidWorks need

16 GB is absolute minimum for simple parts only. 32 GB is industry standard for professional mechanical design handling assemblies of 1,000 to 5,000 parts. 64 GB or more is required for massive assemblies and complex simulations. Also set page file to 2x your physical RAM as fixed size to prevent Low Resources crashes.

What is Enhanced Graphics Performance in SolidWorks

Enhanced Graphics Performance enables the OpenGL 4.5 pipeline that offloads silhouette edge calculations to your GPU instead of CPU. This dramatically improves large assembly rotation frame rates and eliminates CPU bottlenecks during viewport movement. Enable it in System Options > Performance and restart SolidWorks.

How do I fix slow SolidWorks drawings

Use Detailing Mode when opening large drawings. This loads the drawing without underlying 3D model data, reducing 10-minute load times to 30 seconds. You can dimension, annotate, and print in Detailing Mode. For layout work, set views to Draft Quality instead of High Quality to eliminate projection calculation delays.

Should SolidWorks be on SSD or HDD

SolidWorks and Windows must be installed on NVMe SSD. Mechanical hard drives are obsolete for CAD workstations. The random read/write speeds of SSDs are essential for loading thousands of small assembly reference files. Installing on HDD guarantees poor performance regardless of CPU or GPU power.

What are Large Assembly Settings in SolidWorks

Large Assembly Settings automatically trigger when component count exceeds a threshold (default 500). The mode disables high quality transparency, enables lightweight loading, and suspends automatic rebuild. You can customize the threshold in System Options > Assemblies. Lower it to 100 or 200 on slower hardware for earlier optimization.

Discord

Discord

Instagram

Instagram

Youtube

Youtube

TikTok

TikTok